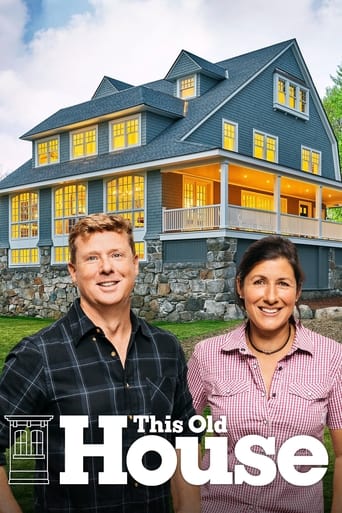

This Old House (1979)

TV's original home-improvement show, following one whole-house renovation over several episodes.

-

Episode 1 - The Acton House - 1

Release Date: 1994-01-01The season begins with a tour of the country's oldest wood-frame house: the Fairbanks House in Dedham, Massachusetts, built in 1636. We then go to the season's project house (and the oldest house the show has worked on): a 1710 colonial in Action, Massachusetts, owned by Terry and Sima Maitland. Though suffering from bad sills and much settling, its real problem for this family of five is lack of space. The Maitlands' $150,000 budget will barely cover an addition, and our master carpenter and Tom Silva advise them to ""let sleeping dogs lie,"" and not attempt to correct many of the original house's problems, which would soak up that amount and more.

-

Episode 2 - The Acton House - 2

Release Date: 1994-01-15The day begins with the crew moving the old milk shed to another spot on the property. Inside, Richard Trethewey has done an energy audit and determined that, with the addition of a stand-by hot water tank, the current heating plant is sufficient to handle the needs of the new addition. Architect Chris Dallmus reviews with the Maitlands the many design ideas they mulled before deciding on the addition's final layout. The need for the addition results from the lack of usable space in the original house. To illustrate the space-eating effect of the large central chimney, our host visits Minuteman National Historical Park and tours a ""naked"" chimney stack with hisorical architect Larry Sorli.

-

Episode 3 - The Acton House - 3

Release Date: 1994-01-28Homeowner Terry Maitland cuts down a tree to make way for the new foundation, while the crew lays out the excavation lines using a small laser level. Excavation contractor Herb Brockert arrives to dig, while out back the old septic field is expanded with a new tank and new leach lines. Inside, the guys review the demolition plans, pointing out the importance of not going beyond the planned areas of reconstruction. Architect Chris Dallmus guides us through a model of the new addition and discusses a possible window choice. Halfway through the excavation, Herb hits large boulders or ledge at about four feet, dashing the Maitlands hopes for a full basement.

-

Episode 4 - The Acton House - 4

Release Date: 1994-02-01We tour the newly demolished back areas of the house, and see how woefully underframed they are. In preparation for the new foundation, the crew suspends the gable end of the old house with ""pins"" of engineered lumber supported both inside and outside the building. Herb Brockert removes part of the old rubblestone foundation, and a small-batch concrete delivery truck pours footings for the addition's lally columns. Steve revisits the Gallants' Victorian to see how they're liking it. A few days later, a performed concrete foundation system arrives on site and is swung into place with a crane. Soon, a transit truck arrives and the crawlspace gets a slab as part of the foundation system.

-

Episode 5 - The Acton House - 5

Release Date: 1994-02-15At the site, lumber - conventional and engineered - has arrived, and the crew begins to attach the sill to the foundation. Terry Maitland lays down fiberboard to protect his old floors during construction, and discusses with our host his concern about the lead content of the old building: one of his children, who has been monitored for the past year, had a slightly elevated blood lead level. Our host promises the show's help. He then takes Terry into the basement, points out how little is holding up the living room, and suggests Terry replace the lally column that somehow got knocked down. We visit a c. 1760 tavern that has been moved across the state and rebuilt as a private home, with painstaking attention to historical accuracy. Back at the site, the first of the wood I-beam joists go in.

-

Episode 6 - The Acton House - 6

Release Date: 1994-02-28The framing crew continues working on the addition; a large steel beam to carry out the upper floor is lowered into place. A framer demonstrates a pneumatic tool for attaching metal hangers to wood. The guys lay down the second floor deck, using construction adhesive and tongue and groove plywood. Inside, we find Terry Maitland putting in a footing for the missing basement lally column. We then meet a lead paint inspector, who uses an x-ray machine to gauge the presence and concentration of lead paint in the old building. Tom Silva works on replacing the rotten and underframed back of the old building. We meet a lightning protection inspector from Underwriters Labs, who assesses the building's system.

-

Episode 7 - The Acton House - 7

Release Date: 1994-03-01With the addtion weatherweight, its massing is apparement and seems to make a successful match with the old building. Inside, Tom Silva shows us the lightweight steel partition walls he's building, and Sima Maitland checks out the new windows and first floor plan. We then tour a plant in Tennessee where power tools - including the circular saw he follows from start to finish - are made. Back at the site, Tom Silva shows us how to the exterior trim on one of the new windows.

-

Episode 8 - The Acton House - 8

Release Date: 1994-03-15Redwood clapboards - finger-jointed and preprimed - start to go on the addition; our general contractor shows us a trick with a ""story pole,"" which helps him space the clapboards evenly across a given field. Our master carpenter explains the challenges of waterproofing and venting the shallow pitch of the addition's shed roof, while in the master suite, we see Dickie Silva screwing down the floor deck with an automatic-feed screw gun. After a tour of the master bath and new second-floor common areas, homeowner Terry Maitland and the lead abatement contractor discuss how the old house's woodwork will be treated during the upcoming deleading process. Our master carpenter warns Terry that the trick will be removing the old windows carefully so as to minimize damage to the interior plaster and exterior siding. Richard Trethewey investigates an old water well discovered on the property - with a proper pump it could supply irrigation water for the yard.

-

Episode 9 - The Acton House - 9

Release Date: 1994-03-28As he contemplates installing replacement windows in the original building, our master carpenter explains that it might make sense to replace the old, heavily weathered clapboards on the fornt facade instead of having to cut each window's trim into them. On the less-weathered west side of the house, the guys shows us just what's involved in installing a replacement window and retaining the original clapboards. We watch the deleading crew in action as they remove lead paint from the original building. Richard Trethewey follows the installation of the well pump and tank, and visits a lab to have the water tested.

-

Episode 10 - The Acton House - 10

Release Date: 1994-04-01Tom Silva shows us his reroofing progress - stripping of old shingles, plywooding sheathing, new shingles, redge vent. Down at ground level, the old clapboards have been stripped off the front facade, revealing the reason for the bellying out of the lower left side. Associated interior demolition reveals wide feathered paneling behind the living room's plaster. The structural deficiency is solved by rebuilding part of the wall. In search of ideas for exterior paint colors, we visit historic Deerfield, Massachusetts, a town of remarkably preserved 18th and 19th century homes. Back at the site, landscape contractor Roger Cook installs a gravel path using steel edging and rice stone.

-

Episode 11 - The Acton House - 11

Release Date: 1994-04-15Homeowners Terry and Sima Maitland puzzle over exterior paint colors, settling on a pumpkin for the field and cream for the trim. They discuss a few details of the farmer's porch that may be reconsidered: a post up against the body of the main house, trim treatment along fascia, and a gutter. Inside, our host checks out a new central vacuum system, while the guys review the heating and cooling systems for the new addition: radiant baseboard downstairs and in the master bedroom, in-wall radiant tubing for mudroom, stairwell, and master bath. Preservation mason Steve Roy diagnoses the fireplaces on the first floor and decides that the chimney should be rebuilt from the roofline up. Finally, landscape contractor Roger Cook supervises hydroseeding of the lawn.

-

Episode 12 - The Acton House - 12

Release Date: 1994-04-28Tom Silva tests out the old-fashioned v-shaped gutter he made for the front porch, then takes us on a tour of the house, explaining his preparations for the spray-in insulation. Most of these are like for any other insulation job, like his use of vent chutes to keep the roof cool, though he did have to cover the windows to protect them from overspray and put up one side of the interior walls for those rooms he wants insulated for sound. Paul Kennedy explains the challenges he faced in working with the house's steel studs. Our master carpenter follows the spray-in urethane insulation process - from mixing the two-part formula on a truck to spraying it into stud bays, where the liquid expands to 100 times its volume, to cutting away the excess to allow for the drywall. The system not only insulates, but acts as a vapor barrier and air sealant as well. Outside, painter George Hourihan reveals some tricks of the trade.

-

Episode 13 - The Acton House - 13

Release Date: 1994-05-01We see Terry busily caulking the battered clapboards of the west gable in preparation for the top coat of paint. Painter George Hourihan applies the gloss latex top coat to body and trim. We join mason Lenny Belleveau to take down and rebuild the chimney from the roofline up. Our master carpenter meets up with archtect Chris Dallmus for a research trip around Action to find the proper design for a new front enterance, since the old one is now too rustic for the house. Sima Maitland reviews her choices for flooring: recycled longleaf and shortleaf southern yellow pine and old white pine. She decides on the white pine, and we visit the lumberyard where it and a wide variety of other 18th and 19th century architectural components are on display.

-

Episode 14 - The Acton House - 14

Release Date: 1994-05-15At in-ground propane tank is installed for cooking and drying. Inside, the wallbaord is up, plaster is going on the ceiling, and Tom Silva demonstrates a new vacuum sander for finishing off the taped seams on the drywall. Richard Trethewey installs a flexible stainless oil-burner flue liner in the chimney, which will prevent flue gases from considering and damaging the mortar and bricks. our master carpenter uses a new jig to drill out holes for the rear exterior door's lock set. Sima visits a tile store to pick out a slate tile, and the Ferrante brothers use a diamond wet saw to cut it before installing it in the mudroom, laundry room and half bath.

-

Episode 15 - The Acton House - 15

Release Date: 1994-05-28We arrive to find Jeff Hosking installing the salvaged floorboards he found in a New Hampshire yard. Jeff discusses the challenges of working with such material, and shows a stationary double-drum sander he uses to take off a little of the boards' rough surface at a time. Upstairs, Joe Ferrante applies a colored grout to the slate tile in the master bath. In the dining room, homeowner Terry Maitland - after checking out a similar house nearby - decides to take down the plaster ceiling, in the hopes that an original beam and joist floor system lurks beneath. Unfortunately, what they find is not very preety... On a more positive front, the guys build a historically accurate entryway for the house back at the workshop. Finally, a new lightning arrest system goes on the building.

-

Episode 16 - The Acton House - 16

Release Date: 1994-06-01The crew installs the new front entryway. Kitchen designer Glenn Berger leads a tour of the new kitchen, and our host takes viewers to the Bath, Maine, showroom and workshop where it was made, Glenn examines the restaurant-style range and hood. Upstairs, painter George Hourihan paints the master bedroom with combination sprayer and roller, while in the master bath, Richard Trethewey shows us how to install a new toilet.

-

Episode 17 - The Acton House - 17

Release Date: 1994-06-15Our host arrives to find installer Michael Griffiths laying out a carpet for the master suite. It's made of recycled soda bottles. Inside, he meets up with Tom Silva, who shows him the new ceiling in the dining room (reboarded, plastered, and given a faux box beam) and explains the work involved in finishing off the replacement windows. Homeowner Terry Maitland discusses with them his expenses for the project (around $190,000) and the amount of donated materials (around $120,000) - the target of $150,000 was exceeded because of all the unforseen work in the old part of the house. Steve meets interior designer Bill Reardon, who explains his approach to the project. Part of it includes a decorative wall finish of joint compound and successive latex paint washes, as applied by artisan Julia Clay. Up in the master suite, the carpet has gone down quickly, and our master carpenter prepares to install brass door hardware. We take a tour of the Reading, Pennsylvania, factory where it was made

-

Episode 18 - The Acton House - 18

Release Date: 1994-06-28The final days. We arrive to find the telephone company burying a new multipair line into the house, leaving the west gable free of overhead wires. Landscape architect Tom Wirth uses a mockup to help Terry Maitland decide where to site the old milk house. Jeff Hosking shows us how he finished the old pine floors to achieve an amber luster. Lighting designer Melissa Guenet gives us a look at the combination of old-fashioned and recessed fixtures, both incandescent and halogen, that she specified for the new spaces. Upstairs, Paul Kennedy installs a paddle fan in the master bedroom's cathedral ceiling, while the crew discusses the remaining problem areas that the Maitlands will someday have to face: sills, drainage, and an unsafe outbuilding. Richard Trethewey takes us on a plumber's final tour through the basement and bathrooms, and interior designer Judy George shows us the decorated rooms.

-

Episode 19 - The Napa Valley House - 1

Release Date: 1995-02-01The crew heads west to California's Napa Valley and Dennis Duffy's circa 1906 farmhouse. Essentially untouched in the last few decades, the house needs a new, larger and brighter kitchen, as well as a new roof and a reinforced foundation. To help out on the project, our host enlists noted Valley architect Jon Lail, whose residences include a shingle-style home being built on the outskirts of St. Helena. Then we check out the work of general contractor Jim Nolan, whose company renovated and rebuilt the offices, winery, and tasting rooms of Merryvale Vineyards in downtown St. Helena.

-

Episode 20 - The Napa Valley House - 2

Release Date: 1995-02-08Work begins on the Duffy residence, with Jim Nolan's crew tearing off the back porch with a backhoe. We visit architect Jon Lail's office to see the proposed kitchen addition and are treated to a ""virtual reality"" walk-through of the space as constructed by computer designer David Munson of HOK Architects, a large firm that employs the technique to present and analyze its large commercial projects. Our host visits Sterling Vineyards, a remarkable architectural statement perched on a mountain at the northern end of the valley. Back at the house, the septic tank has collapsed under the weight of the backhoe, and job foreman Jeff Castille shows us the termite damage and crumbling foundation that further demolition has revealed.

-

Episode 21 - The Napa Valley House - 3

Release Date: 1995-02-15After a period of heavy rains and flooding, Napa Valley - and the jobsite - are a soggy mess. The show opens in sandbagged downtown Napa, then head to the job, where foreman Jeff Castille and crew have spent the week levelling the kitchen area with steel beams and hydraulic jacks. Jeff shows us the water level he used. Outside, the concrete truck arrives to pump in the mix for the steam walls. On site, our master carpenter visits a rammed-earth house being constructed on a nearby hillside. Our host checks out the condition of Dennis's roof with roofing contractor Mike McDermott, and Richard Trethewey takes Dennis to a San Francisco bath showroom to consider choices for his bathroom and kitchen.

-

Episode 22 - The Napa Valley House - 4

Release Date: 1995-02-22The show start with a visit to Napa Valley's oldest wooden, gravity-fed winery, home of Trefethen Vineyards. At the site, our master carpenter meets plumber George Biter, who shows his rough work, including ABS and cast iron piping. General contractor Jim Nolan describes how a large laminated-veneer-lumber beam was hoisted into place, spanning the new kitchen and precluding the need for a mid-room support post. New French doors go into the west wall of the old dining room, and our host visits the Palo Alto factory where the energy-efficient plastic film inside the glazing is made. Back on site, we check out the foundation plantings that are threatening Dennis's house, and take a look at Dennis's little vineyard. Then it's off to the other extreme of the winemaking art: Opus One, a joint venture between the valley's Robert Mondavi and France's de Rothschild family.

-

Episode 23 - The Napa Valley House - 5

Release Date: 1995-03-01We check out the mustard plants in a vineyard near the farmhouse before heading over to a very busy jobsite. There, contractor Jim Nolan shows us the extra work that has had to be done to save us the old front porch; the chimney has also been torn down. The roofing crew strips and sheathes the old roof, which has been straightened and reinforced with purlins and braces. Job foreman Jeff Castille shows us around the newly framed kitchen and we meet electrician Al Curtice, who is installing incandescent can fixures and a fluorescent valence light around the kichen ceiling soffit. We tour the champagne caves of Schramsberg Vineyards, while our master carpenter visits a crew who is busy digging a cave for a new winery. On site, Dennis meets with kitchen designer Paul Price to lay out the proposed cabinet footprint and choose cabinet door patterns and finishes, as well as solid surface countertops.

-

Episode 24 - The Napa Valley House - 6

Release Date: 1995-03-08With remarkable progress at the site, we tour the exterior with Jim Nolan, seeing fir decking, trim details, traditional redwood siding and a synthetic stone facing for the foundation. Meanwhile, our master carpenter visits a nearby factory where wine barrels are made from American oak. Back at the site, our host sees the new semi-custom kitchen cabinets being installed - their features include solid-oak white-stained faces, morticed European hinges, full-extension, dovetailed, solid-wood drawers, and a two-part epoxy finish. The oak floor has been installed - quartersawn 5/16"" x 2"" strips with a walnut inlay - and we catch up with floor man Ron Spiteri to see how it went down. The next phase of finish work is mouldings and trim, and we see how finish carpenter Jim DePriest handles the casework around a door.

-

Episode 25 - The Napa Valley House - 7

Release Date: 1995-03-15The show opens at Clos Pegase, a winery designed by noted architect Michael Graves. At the site, the rains continue, and so does progress. Our master carpenter follows the installation of the solid-surface countertop, while Richard Trethewey points out the important features of the new hot-water system: earthquake strapping, a circulating pump on a timer and the magnesium rod which prevents corrosion of the tank. A water softener goes in, and electrician Al Curtice installs a three-way dimmer that dims from two locations. Finally, we tour a remarkable winery property that's for sale in St. Helena.

-

Episode 26 - The Napa Valley House - 8

Release Date: 1995-03-22The final day opens at a scenic overlook on the first clear day in a week. On site, the painters are applying the exterior topcoat, carpenters are cutting the last pieces of trim and architect Jon Lail is on-site to check out the final product. Meanwhile, Richard Trethewey shows us the utility room - a small toilet and shower room, a lavatory and a laundry with plenty of storage space. The kitchen has an island sink with water purification unit; a trash compactor; three-bowl sink with disposal; two undercounter thermal-convection ovens; a quiet dishwasher with a pause function (for turning on after people have left the room); a gas cooktop with retractable hood; and a built-in refrigerator that operates for around $85 a year. The push towards more efficient appliances and buildings began in California, and Richard meets with the chairman of the state's energy commission to learn about its programs. We see custom wood doors and brass hardware go in, then visit a stunning private wine ce